Products

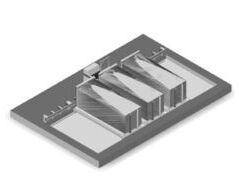

Stationary compaction plants

Stationary compaction plants are particularly suitable for high waste volumes. From small systems to large systems with e.g. We offer everything for presses or containers. For these presses, we manufacture containers with a useful capacity of 6 to 25 m³. The systems are equipped with a PLC control and can thus be adapted to the local conditions.

Due to the possibility of delivery with a wide range of accessories, each device can be tailored to the specific requirements of the respective source.

We want to mention some of these here:

- Lift-tilt device for e.g. 1,100 l container

- Hydraulic container lock

- Trolleys for press / containers

- Garbage disposal chutes

- Connection to an extraction system

- Pre-full notification

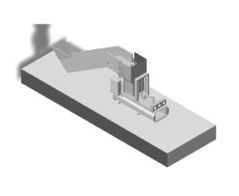

Presscontainer

These systems are used where flexibility is required and the volume of waste is not so high. No foundations are required to use a press container. However, it should be noted with these systems that the compression ratio is only approx. 1: 5, and thus only a smaller proportion of waste can be compressed than with a stationary compression system. We manufacture press containers in sizes 6 - 26 m³ net capacity.

The filling can also be adapted to customer requirements. Whether filling from the floor, ramp design, lifting and tilting device, connection to the suction system, waste disposal chutes, etc. The press container always enables mobile use at the waste or paper waste location.

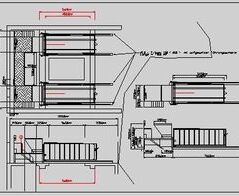

Balers

Balers are hydraulically driven presses that press into a conically converging open channel. The pressed and fully automatically bound (option) bales can be transported and stored economically.

Regardless of whether you want to press paper, cardboard, film or residual waste, whether you run a supermarket, a landfill or a recycling center, a wide variety of sizes, performance levels and designs offer the optimal solution for every user.

Baling presses are available as simple press units with manual binding up to the large channel baling press with autom. Bonding and a throughput of up to 20 tons / hour.

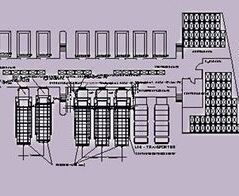

Disposal centers

The separation of garbage, residual waste, paper, plastics, etc. is an important factor today in order to save costs and, on the other hand, to make a small contribution to relieving our environment.

We also support you in the planning of disposal centers, from planning and project planning through to implementation. E.g. a separation can be achieved by installing a stationary waste press system with a driving device to various containers.

But also the installation of various compression systems for various waste products, as well as the integration of e.g. Glass containers, etc. can be detached as required.

Our area of responsibility also includes the planning and implementation of recycling yards for cities and municipalities, in which the citizen himself directly separates the waste.

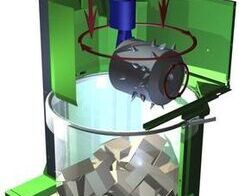

Round bale compacting system

The baler combines the advantage of continuous fillability with the efficient collection of waste and garbage directly at the point of origin. The compression takes place directly in a 1400 liter PE film sack, which can be transported with a previously inserted Euro pallet. Low space requirements and high compaction results lead to the greatest cost savings, since expensive and space-consuming large containers can be replaced.

It goes without saying for the PS 1400-E that the high Bergmann quality level of a constructively and technically mature product and the quiet, low-maintenance drive.

- Waste compactor (baler) for recyclable waste and residual waste

- Shredding and compaction of the filling material through right / left rotation of a specially equipped steel roller

- Continuous fillability

- Waste compaction in a 1400 liter PE film sack

Way of working

- Suspend a 1400 liter PE film sack in the baler

- Continuous filling by everyone via the large chute

- Collection, crushing and compaction of the waste by rotating special roller

- The highly compressed material can be easily removed and transported away using a pallet truck or a previously inserted Euro pallet.

- Subsequent collection by the disposal company